- Publisher

- United Nations Industrial Development Organization

- Authors

- Ysanne Choksey, Kajol, Julian Somers, UNIDO Net Zero Partnership

- Version number

- 1.0

- Publication date

-

2 October 2025

- Pages

- 1

- Project

- Produced within the framework of Global Steel Transformation

A timeline of technologies for decarbonising steel

Summary

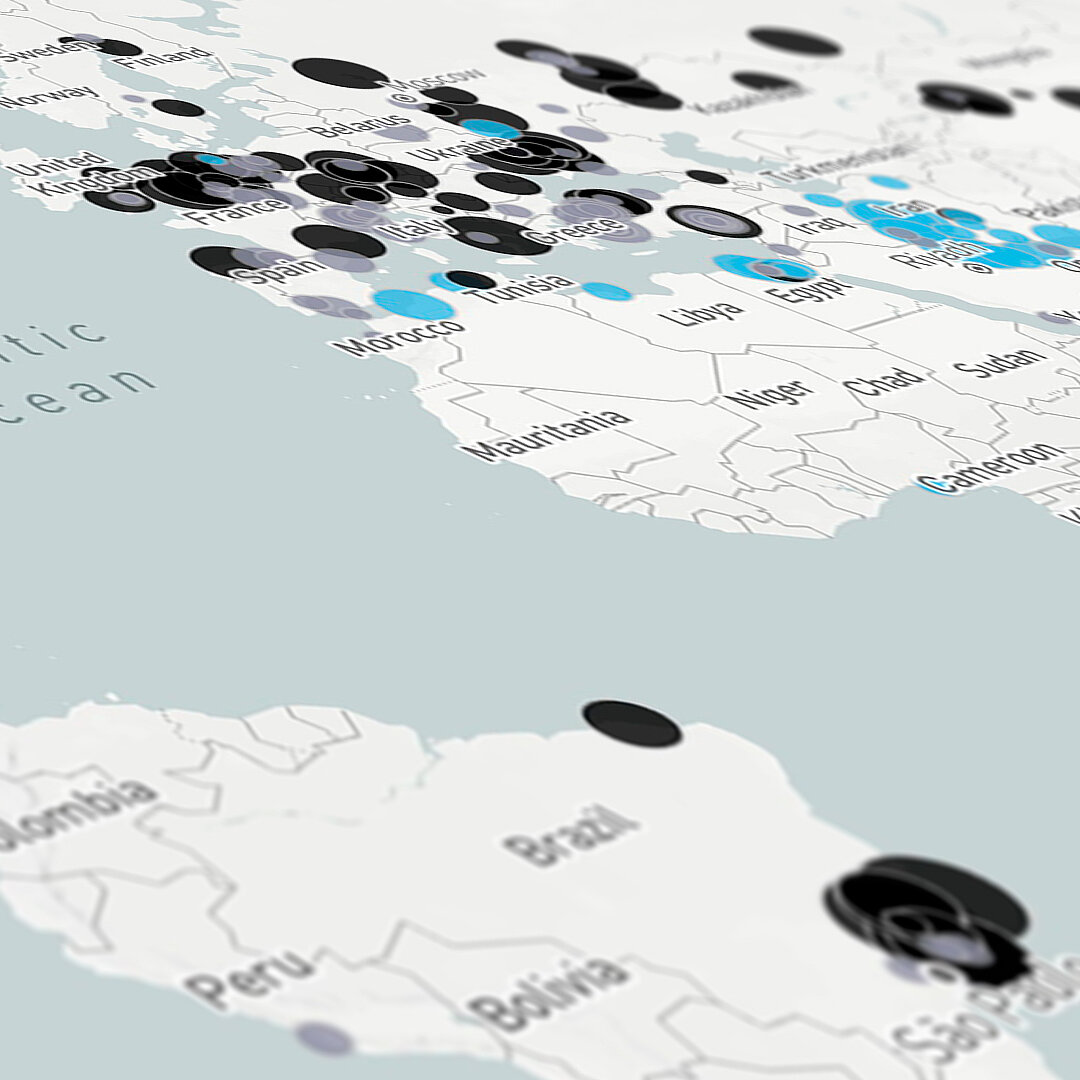

This explainer presents a timeline of technologies for decarbonising steel, outlining the short-, medium- and long-term solutions needed to reduce emissions across the steel value chain. Steel production still contributes significantly to global energy-related carbon dioxide emissions, largely due to heavy reliance on coal. Achieving near-zero emissions by mid-century will require a portfolio of technologies, with choices shaped by local conditions such as electricity mix, furnace age, scrap availability and access to finance.

In the short term, widely available measures can deliver immediate emission reductions. These include energy and process efficiency improvements, greater scrap use and recycling, partial fuel substitution, electrification of auxiliary processes and expanded use of electric arc furnaces (EAFs) powered by low-carbon electricity.

By the medium term, deeper cuts depend on scaling emerging solutions such as hydrogen-based direct reduced iron (H₂-DRI) combined with EAFs, hybrid DRI–BOF routes, carbon capture on blast furnaces and hot briquetted iron (HBI) trade.

In the long term, post-2040 pathways include electrolysis-based steelmaking technologies that eliminate the need for coal or hydrogen. Across all time horizons, material efficiency and circular economy approaches are critical to reducing steel demand and emissions, while transitional technologies must be paired with clear plans to phase out fossil-based production.

![The global steel industry can achieve net-zero emissions by the early 2040s [Translate to English:]](/fileadmin/_processed_/8/f/csm_15_insights_global_steel_news_73f640a802.jpg)

![Shifting global steel reinvestments from coal to clean [Translate to English:]](/fileadmin/_processed_/9/e/csm_global-steel_project_news_2_283e600f74.jpg)